AGM Battery for Boat

An AGM battery for boat is the obvious choice and I have been installing AGM boat batteries on my own boats for a long time now as well many others. The performance and practicality have been right up to expectation, and in spite of the Lithium-ion revolution will keep using them. Whilst most boaters have long since switched to AGM boat batteries now the Lithium-ion battery is making rapid inroads and that will be covered elsewhere. What is an AGM battery for boat called AGM? The reason is that the electrolyte within an AGM boat battery is held within a very fine microporous (boron-silicate) glass matting that is sandwiched between the cell plates. This absorbs and immobilizes the electrolyte solution while still allowing the required plate interaction. They are also sometimes referred to as starved electrolyte batteries, as the glass matting is only 95% soaked in electrolyte.

The Marine Electrical Electronics Bible is now out, buy and save money, make your boat more reliable and be self sufficient.AGM Battery for Boat

They are often simply referred to as Absorbed Glass Mat (AGM) or sometimes they are also called Valve Regulated Lead Acid (VRLA) Batteries. There are many manufacturers and among the most reputable AGM boat batteries manufacturers and suppliers are Lifeline Batteries, Trojan Batteries and Rolls Batteries and Mastervolt.

AGM Battery for Boat

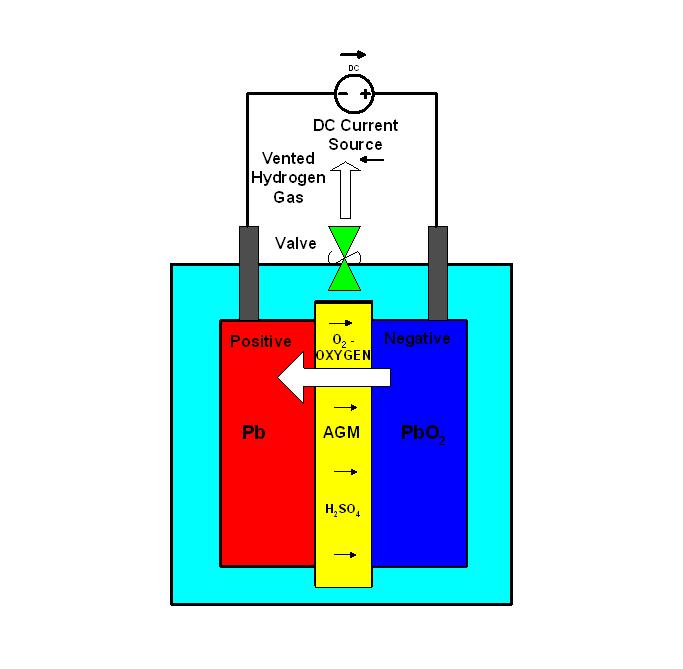

Recombinant Gas Absorption Principles. In a normal wet flooded cell lead-acid battery, water loss will occur when it is chemically broken down into oxygen and hydrogen near the end of the charging cycle. In a battery during charging, oxygen will evolve at the positive plate at approximately 75% of the nominal full charge level. Hydrogen evolves at the negative plate at approximately 90% of full charge. In normal open flooded cell batteries, the evolved gases disperse to atmosphere, resulting in electrolyte loss and periodic water replacement. These are the bubbles that can be seen in the cells during the battery charging cycle. During battery charging the current causes decomposition of the water, and oxygen is evolved on the positive plate.

The oxygen then migrates through the unfilled pores of the separator matting to react with the negative plate and form lead oxide, lead sulfate and water. The charge current reduces and does not generate hydrogen. The low maintenance recombinational battery has different characteristics. The plates and separators are held under pressure. In AGM boat batteries during charging, the evolved oxygen is only able to move through the separator pores from positive to negative, reacting with the lead plate. The negative plate charge is then effectively maintained below 90% so inhibiting hydrogen generation. They emit less than 2% hydrogen gas during severe overcharge (4.1% is flammable level).

Read more about AGM batteries in the Marine Electrical and Electronics Bible.

AGM Boat Batteries

Plate Construction. There are variations to flat plate manufacturing techniques. The Optima® AGM boat batteries have a spiral cell, dual plate construction. Another important feature is a greater shock and vibration resistance than gel or flooded batteries. They also have extremely high CCA values of up to 800 amps at 0˚F.

AGM Boat Batteries Charging.

Charging of AGM battery for boat have relatively few limitations, and there are no special charge settings that are required for charging devices such as alternator regulators or battery chargers. Typical charge voltages are in the range 14.4 to 14.6 volts at 68°F (20°C). The batteries have a very low internal resistance, which results in minimal heating effects during heavy charge and discharge. They can be bulk charged at very high currents, typically by a factor of five over traditional wet flooded cell batteries, and by a factor of approximately 10 over gel type batteries. They also allow 30% deeper discharges which is a big advantage in deep cycle boat applications. The AGM battery will also recharge approximately 20% faster than gel electrolyte type batteries, and importantly they possess much better recovery abilities from deep discharge conditions. One important feature is that the self-discharge rates of AGM boat batteries are only 1%-3%.

If you are a weekend, harbor or river cruiser, who does limited motoring periods, or leave the boat unattended for long periods, the AGM boat batteries are a viable proposition. As mentioned AGM boat batteries have very low self-discharge rates, and very high recovery rates from deep discharges. If a small solar panel is left on, or a wind generator with a suitable regulator, they will recoup the annual costs of replacing deep cycle batteries by lasting several seasons, with the more important improvements in reliability. Typical charge voltage levels are 100% is 12.8–12.9 volts, 75% is 12.6 volts, 50% is 12.3 volts, 25% is 12 volts and 11.8 volts is flat.

AGM Boat Batteries

AGM Boat Batteries Heat Resilience. At high temperatures AGM boat batteries (and Gel electrolyte cells) are unable to dissipate the heat generated by oxygen and hydrogen recombination cycle and this can create a condition known as thermal runaway. This can and will lead to gassing and the drying out of the battery cells. A premature loss of capacity can occur when the positive plate and grids degrade due to higher operating temperatures. This is caused by the exothermic recombination process and higher charge currents. In addition, negative plates also degrade due to inadequate plate conversion. The main failure modes are cell shorting and pressure vent malfunctions caused by manufacturing faults. All about AGM Boat Batteries and the boat battery.